| Model | TGYF-C | |||

| Volume | 50ml | 100ml | 250ml | 500ml |

| Pressure | 16MPa | |||

| Temperature | 300℃ | |||

| Stirring speed | 1800 r/min | |||

| Heating power | 0.6kW | 0.6kW | 0.8kW | 1.0kW |

| Heating mode | Modular electrical heating | |||

| Stirring method | Magnetically coupled stirring | |||

| Material | Stainless steel 304, 316 | |||

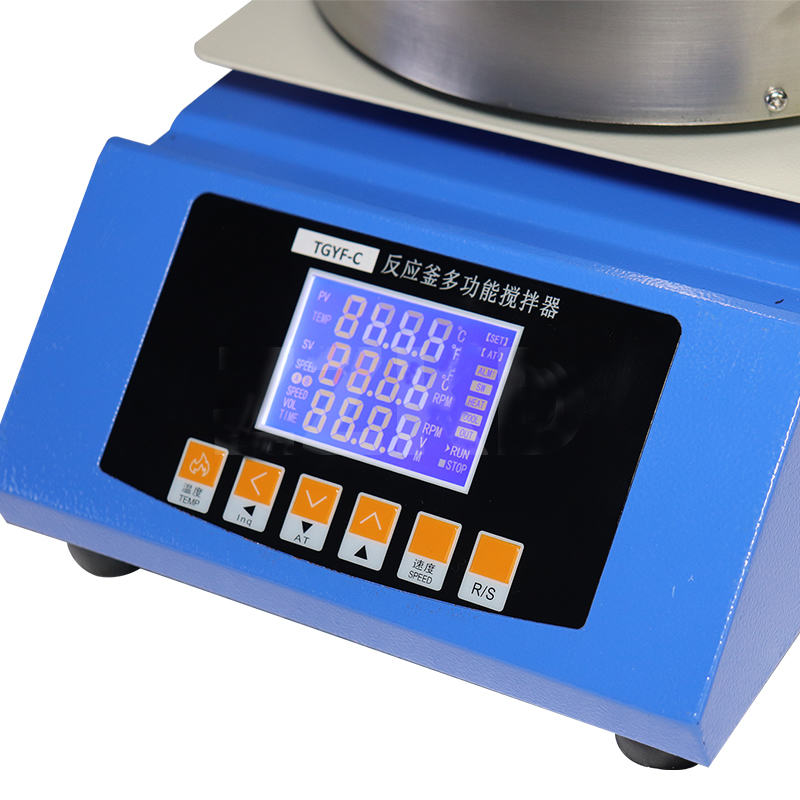

| Display method | S creen digital display | |||

Product Description:

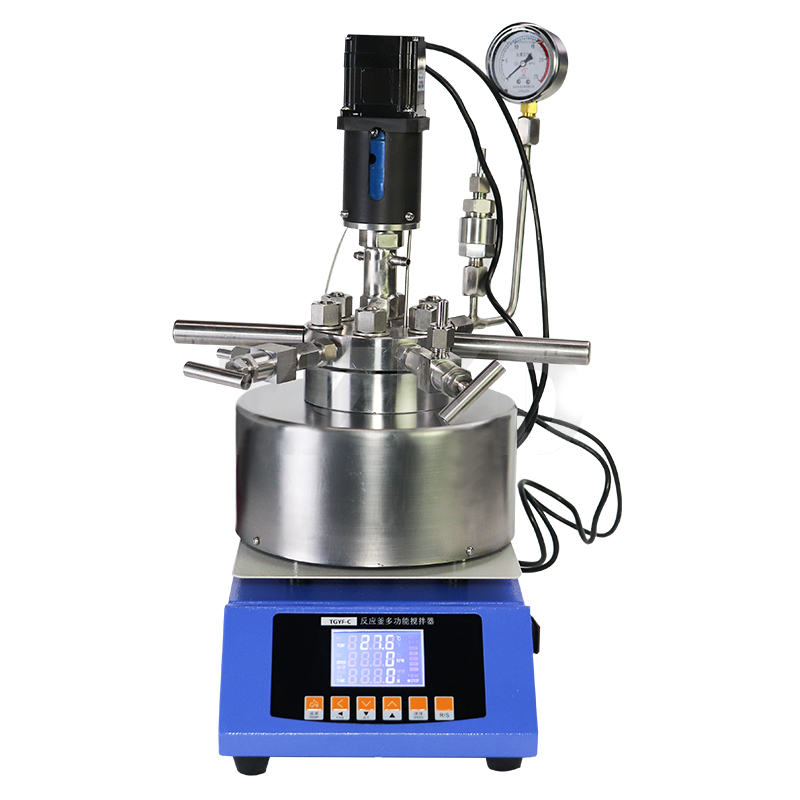

Laboratory Strong Acid and Strong Alkali High Temperature and High Pressure Mechanical Stirring Reactor body of the reactor is processed by a large processing center at one time. This reactor is composed of quick-opening type and uses 6 high-pressure bolts. This type of reactor is mainly used for laboratory experiments such as large-viscosity, high-temperature and high-pressure scientific research, microanalysis and quantitative synthesis. The reactor is suitable for In the fields of petrochemical, pharmaceutical, polymer synthesis and metallurgy, it can be used for catalytic reaction, polymerization reactor, supercritical reactor, high temperature and high pressure reaction, hydrogenation or inert gas protection reaction, etc.

| Volume | 25-1000ML | 50-1000ML |

| Kettle Body Material | 304, 316L, 310S, 904L, Hastelloy alloy, titanium, etc | 304, 316L, 310S, 904L, Hastelloy alloy, titanium, etc |

| Sealing Style | Hard/soft sealing | / |

| Kettle Body Structure | Quick-open type | / |

| Liner | Ptfe/quartz /316L/ Hastelloy/titanium/Monel etc | PTFE/quartz /PPL |

| Temperature | 0-350℃ | 0-600℃ |

| Thermocouple | K type | K type/316L/φ2.0 |

| Pressure | 0-25MPA | -0.1-25MPA |

| Explosion-proof Pressure | 7-26MPA | |

| Explosion-proof Device | Hastelloy alloy material | Hastelloy explosion-proof film |

| Stirring | Internal Magneton Stirring | Shaft-driven blade stirring (torque up to 40KG) |

| Stirring Speed | 0-1500RPM | 0-1000RPM |

| Control Cabinet, Heating Furnace | One-piece construction | / |

| Heating Power | 500-5500W | 500-2500W |

| Heating Equipment | Fully enclosed stainless steel heater | |

| Heating Method | Electrical Heating | Module Heating |

| Operation Interface | 7 Inch true color touch screen display | LCD display, key operation |

| Control System | USA Imported PID intelligent dual temperature control system, temperature control program, main control kettle temperature, auxiliary control furnace temperature |

PID intelligent double temperature control, effectively prevent impact temperature, temperature control program (optional) |

| Zones of Temperature Control | Intelligent selection of temperature control for four groups of temperature zones (temperature range can be set independently) | / |

| Power Adjustable | Four groups of zone temperature and power adjustable | / |

| Temperature Display | 0.1℃ | / |

| Temperature Control Accuracy | ±1℃ (no strong exothermic/endothermic/temperature measuring tube without tetrafluoride Coating) | ±1℃ |

| Temperature Setting | Double self-setting function, kettle temperature and furnace temperature PID self-setting temperature function |

/ |

| Safety Interlocking | Overtemperature/overpressure/timeout alarm, stop working, cut off heating | / |

| Timing Function | Insulation timing and start-up timing | / |

| Torque Display | Magnetically coupled torque display | / |

| Data Copy | Furnace temperature, temperature in the kettle, pressure, speed, torque and time can be exported through USB interface data or cut graph |

/ |

| Remote Control | Through network cable interconnection, it can be operated on a computer, or connected to a LAN mobile phone for remote control (remote monitoring needs to open a cloud server by itself, and the seller provides technical support) |

/ |

| Inlet Valve | 316L stainless steel needle valve, interface size φ3/φ6 | / |

| Gas Outlet Valve (Sampling Valve) | 316L stainless steel needle valve, interface size φ3/φ6 | / |

| Spanner | Special dismantling tool | / |

| Power Supply | 220V/110V | |

| Option | PTFE Cover Reactor Lid , temperature tube, stirring rod and stirring blade, PTFE liquid sample tube, support, screen, etc.; External condensation reflux, etc |

|

Laboratory Sterilizer Polymerization Magnetic Stirring High Pressure Temperature Autoclave Stirred Reactor Advantages:

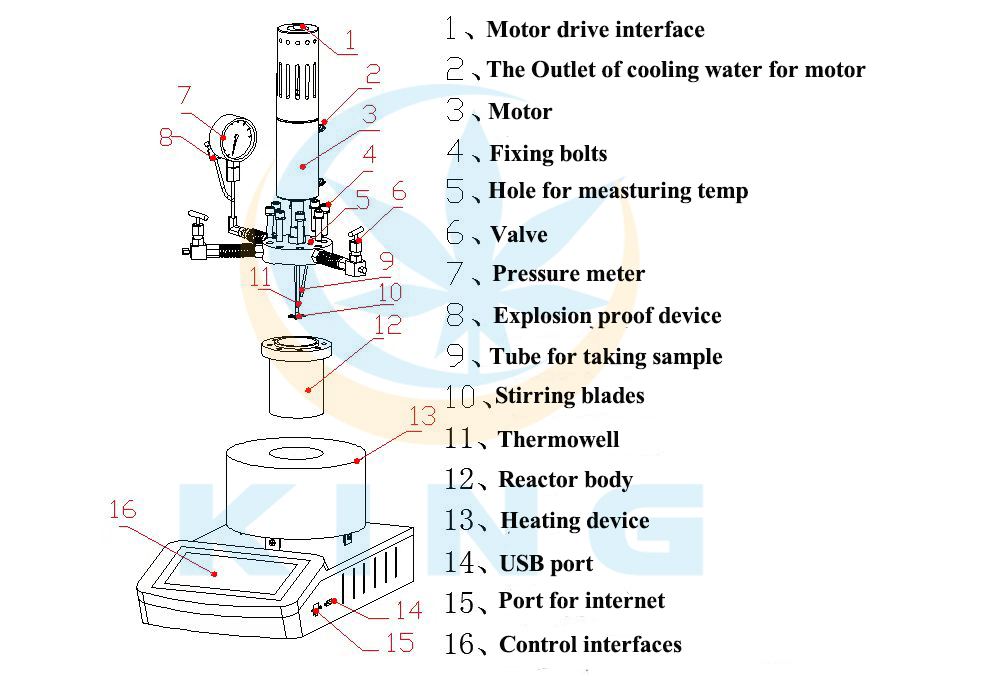

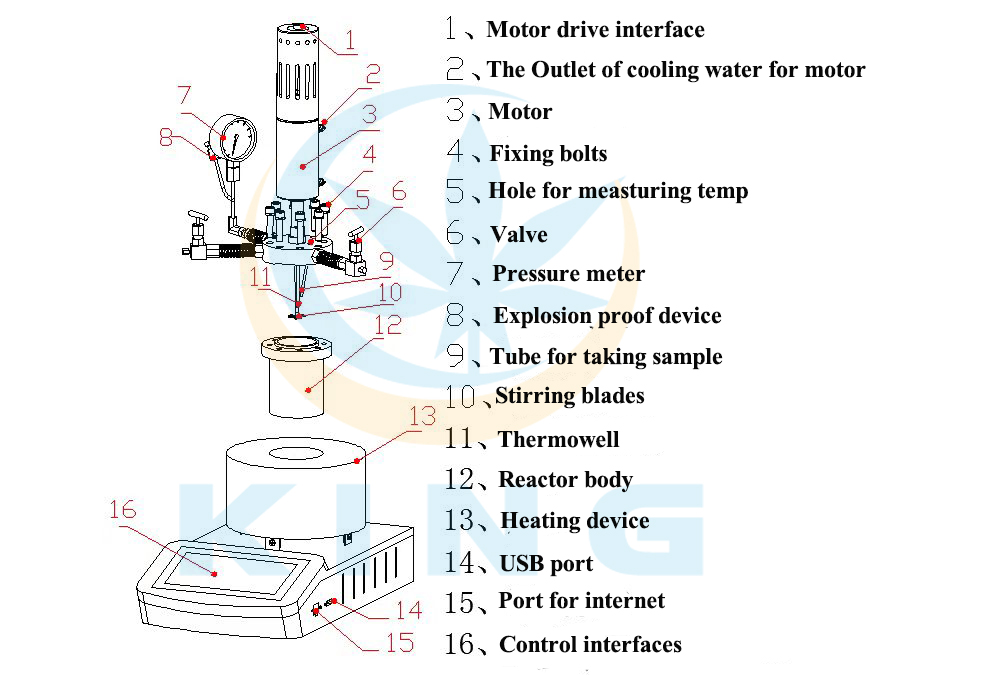

1. Kettle body material: SS3160material is used, other materials can also be selected according to the customer’s specific requirements for the reactant medium.

2. Heating device: fixed modular electric heater, uniform and stable heating, durable.

3. Stirring device: magnetic coupling paddle stirring,

4. Temperature control device: LCD display, dual-channel temperature control system,adopts advanced PID artificial intelligence temperature control, has auto-tuning (AT) function, has timing function, can be forward and reverse, (see the instrument instructions for details).

5. Temperature measuring device: high-precision temperature sensor, deep into the reactor body, real-time monitoring of the reaction temperature in the reactor The kettle body and heater can

be completely separated, which greatly facilitates the disassembly of the reaction kettle and improves work efficiency;

6. Brushless motor: stable speed and low noise;

7. Inlet needle valve: gas inlet needle valve with a 3mm ferrule;

8. Exhaust needle valve: It is convenient for vacuum treatment of the system and the use of replacement gas before the reaction, and it is used as a vent valve after the reaction;

9.Stainless steel pressure gauge: German imported pressure gauge WIKA, real-time monitoring of the internal pressure of the kettle reaction;

Reviews

There are no reviews yet.