| Basic parameter |

Product name | Auto Lifting Glass Reaction Kettle |

| Glass material | GG-17 | |

| Framework material | Anti-corrosion coating | |

| Moving method | The band brake type universal angle wheel | |

| Reactor tank volume | 10L 20L 30L 50L | |

| Jacket capacity | 8L – 16L | |

| in and out of the oil circulation | Low “in” and high “out” | |

| Number of kettle lid bottle | six mouth | |

| Discharge height | self-regulation | |

| Reaction temperature of reactor | -80-250℃ | |

| Vacuum | 0.098Mpa | |

| Stirring running speed | 0-450pm | |

| Diameter of stirring shaft | 17mm | |

| Stirring power | 90W1/3 | |

| Voltage(V/Hz) | 220V/50Hz | |

| Lifting power | 90W3/1 | |

| Lifting stroke | 730mm | |

| Exterior size(mm*mm*mm) | — | |

| Packing size(mm*mm*mm) | — | |

| Packing weight(KG) | — | |

| Speed regulation method | Electric stepless speed regulation | |

| Function configurations | Motor configuration | Power motor at low speed, speed ratio is 3:1 |

| Rotary speed display | LCD digital display | |

| temperature display in bath | Digital display | |

| Sealing method | Four fluorine component seal, flange Φ 60 stirring | |

| Temperature measuring tube | 24#standard opening | |

| Solid feeding opening | ¢80 flange mouth with four fluorine cover | |

| Discharging method | Inclined glass charging valve 80 flange opening | |

| Vacuum display method | Vacuum meter | |

| Stirring connection method | Cardan joint connected | |

| Stirrer | Tracing type + spiral stainless steel rod, outsourcing 4 fluorine | |

| Bath shell | 304 stainless steel | |

| Optional configurations |

Insulation device | Detachable insulation cover |

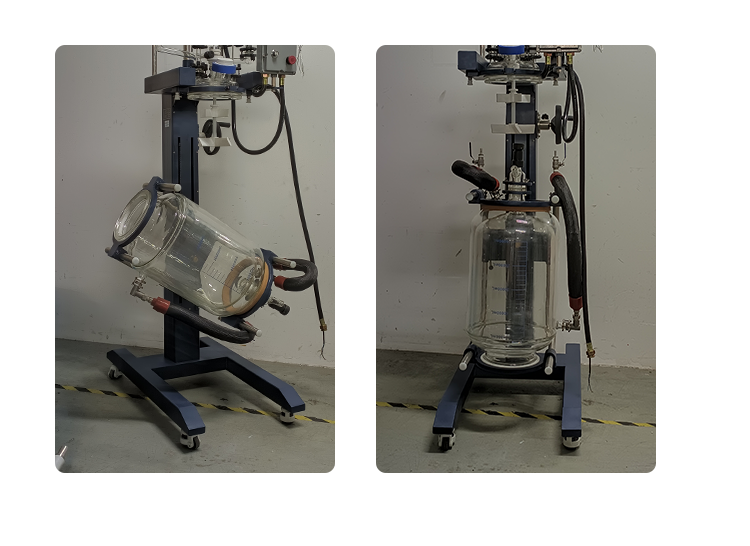

The Lab Electric Lift Double Jacketed Glass Reactor is the most advanced reactor on the market. This unit has a built in lift that can raise the entire lid up or down with the touch of a button. Our Auto Lifting Glass Reaction Kettle also have a hand crank in the back to allow near 180° tilt of the jacketed vessel. With these two features, reaction has never been simpler.

Associated Equipment

Low temperature cooling liquid circulating pump (Cooling chiller): Low temperature reaction and re-flux, condensation.

Circulating water/oil bath: Thermal power.

High and low temperature all-in-one: High and low temperature experiment reaction

Circulating water vacuum pump: To provide a vacuum source.

Chemical Lab Auto Lifting Glass Reaction Kettle are mainly used for synthetic reaction, distillation and concentration of different types of materials. We have single wall, double wall and triple wall glass reactors. The reactor can be pumped to a negative pressure state according to some experimental requirements. A constant pressure funnel or an adjusting valve on the feeding bottle allows you to add material to the vessel at a uniform and controlled speed. Condenser helps to recover some materials distillate during reaction. Circulating liquid can be filled into the jacket to heat or cool materials inside. Triple wall glass reactor with two jackets, the inner jacket is for circulating liquid, and the outer layer should be pumped to vacuum condition for thermal insulation. can realize constant temperature heating by injecting conduction oil into jacket. Separating material by the sand core or PTFE core plate placed at the bottom. Vacuum can be achieved during reaction process. It is a new type of solid-phase separation reactor, which is an ideal test and production equipment for modern synthetic chemicals, biopharmaceuticals and new material preparation.

Each Electric Glass Reaction Kettle has an inner jacket allowing circulation of liquid, while the outer jacket allows for vacuum insulation. This creates higher chilling or heating efficiency as well as less temperature loss. Each jacket is able to be drained and released of pressure with ease, due to the convenient drain ports near the bottom portion of the reactor.

No expense has been spared with these Efficient Electric Glass Reactor Kettle, yet we crush the market on pricing to provide great value at a low cost. Our reactors are the best value on the market and each one comes with fantastic customer service.

PTFE mechanic stirring seal

PTFE seal and ceramic sealing rings are used for sealing, which is anti-corrosion, anti-wear, high sealing vacuum degree.

New type PTFE and glass discharge valve

The combination of high borosilicate glass and PTFE discharge rod design is resistant to corrosion. Also there is no dead corner at the bottom of reaction kettle, so no liquid accumulation exists during discharging.

High borosilicate glass

With high-tech firing method, the high borosilicate glass has stable chemical performance, high strength, high hardness and high light transmittance. High and low temperature conversion is not easy to crack, much safer to use.

Manual or electric lifting

Manual lifting mode is the kettle body moving down, electric lifting type is the kettle cover and above accessories moving up.

Rotate 180 degree

The kettle body can be manually rotated by 180 degrees to directly pour out the relatively thick materials or discharge the liquid directly from the bottom valve, easy to operate and clean.

Speed control motor

All copper brushless variable-frequency speed regulating motor, no brush, no spark, low noise, safety, stability, long life, overload protection, constant speed, stable starting. Explosion proof motor is optional.

Serpentine coil condenser, excellent air tightness, high vapor condensation efficiency.

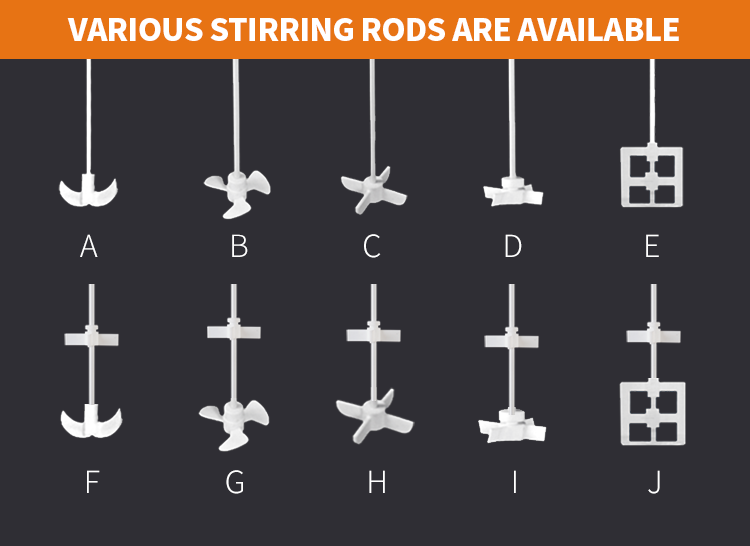

Various stirrers

Stirrer material is 316L stainless steel wrapped with PTFE coat, which has high corrosion resistant performance. (316L stainless steel material optional) Stirring blade can be customized. We also provide various blade shape for your reference.

Serpentine coil condenser

Serpentine coil condenser, excellent air tightness, high vapor condensation efficiency.

Bring your lab to the next level, and get started with a Lab Electric Lift Jacketed Reactor today!

We ship all glassware products with additional care, but sometimes they arrive broken. If glassware arrives broken, please contact us within 3 days of receiving your product and we will either send you a brand new piece or send you a refund! Any glassware broken after delivery voids all warranties. Thank you for understanding!

For Technical Support, Questions, or Other Issues Please Email or Call Us!

Our Service

If you face any problems in future during the testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation manual. We can provide video-conference.

1. Pre-service

24 Hours online service for your consult.

* Inquiry and consulting support.

* Quick response with detailed quotation

* Confirm price, quantity, shipment, lead time and payment terms)

Help choose the right model, and a series of service, person, advise.

1) More than 10 years manufacturer experience in test equipment and with strong research and development team.

2) Accepted of customization for all kinds of special specification products.

3) We value the inquiry sent to us timely, ensure quick and competitive offer.

2. After sale service

1) We deal with your complaints within 24 hours and solution provide within 3 working days.

2) Training how to install the machine, training how to use the machine. We would offer operation video and English operation muanual. We can provide video-con.

3) 1-year warranty service and all life maintenance; our engineers could go to your place for better service necessarily.

3. Commitment:

We will sign a letter of commitment while we sign the contract, which will improve your confidence in us.

5. Good Packaging:

Good Packaging: All goods are covered with film and air bubble film before put them into the strong wooden case.

FAQ:

1. When can the goods be delivered?

2-5 working days after payment for regular models and 5-10 working days for a customized model.

2. Can you accept OEM or ODM?

Yes, we can.

3. How to choose the suitable equipment?

Tell us your requirements, our professional sales will introduce you the most suitable model

We ship all glassware products with additional care, but sometimes they arrive broken. If glassware arrives broken, please contact us within 3 days of receiving your product and we will either send you a brand new piece or send you a refund!

Any glassware broken after delivery voids all warranties. Thank you for understanding!

Reviews

There are no reviews yet.